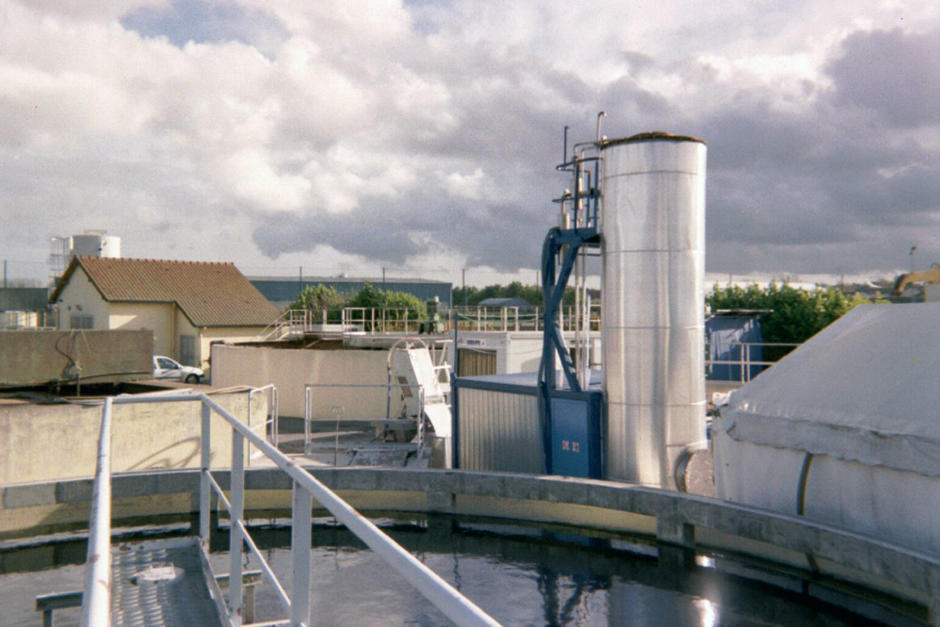

Bio Thelys™

Bio Thelys™ is a complete sludge reduction solution that works in batch mode, combining thermal hydrolysis and anaerobic digestion.

By coupling the thermal hydrolysis and the anaerobic digestion, Bio Thelys™ offers better performance than a conventional digestion and optimizes sludge treatment by producing:

- 25 to 35% less dry matter

- 30 to 50% more biogas

- No odours

- A pasteurised digestate, for full control over the sanitation hazards and safe agricultural reuse.

Bio Thelys™ handles all kinds of organic, industrial or municipal sludge and can also handle grease. Using Bio Thelys™ process allows to:

- Reduce sludge volume

- Improve sludge quality

- Increase biogas production

Features and Benefits

Bio Thelys™ is a flexible and safe solution which produces a pasteurised digestate that is compliant with international standards e.g.: EPA class A (UAS) and ADAS Safe Sludge Matrix (UK)

Bio Thelys™ allows:

- Reduced digester related investment for new installations

- Reduced operating costs:

- Less sludge to remove

- At existing installations, the digestion capacity can be increased by handling new input.

- An income which is generated from:

- Either processing external input through co-digestion

- Either selling the energy produced by co-generation or producing bio-methane

Bio Thelys™ is a solution that guarantees energy and environmental performance, thanks to:

- Conversion into “green” electricity via co-generation

- Bio-methane production (for injection into the network or as fuel)

- Complete sludge pasteurization

- Reduced carbon footprint of the facilities

- Many possibilities for using biogas: with external input (co-digestion), energy self- sufficiency or even a positive energy footprint may be achieved by the plant.

Bio Thelys™ combines with other Veolia sludge treatment processes such as Athos™ (hydrothermal oxidation), Pyrofluid™ (incineration), BioCon™ (thermal drying), Solia™ (solar drying) and completes them to offer even more sustainable solutions.

References

- Oxford, United Kingdom, 2013: 230,000 PE* and 26,000 t DS/year**

- Esholt, United Kingdom, 2013: 760,000 PE and 32,800 t DS/year**

- Tergnier, France, 2011: 30,000 PE and 1,600 t DS/year**

- Monza, Italy, 2010: 750,000 PE and 15,800 t DS/year

- Le Pertuiset SIVO, France, 2008: 80,000 PE and 2,000 t DS/year

- Château-Gontier, France, 2007: 38,000 PE and 1,000 t DS/year

- Saumur, France, 2006: 60,000 PE and 1,600 t DS/year

*PE: Population Equivalent **including sludge external input